Seamless Filter Production using Ultrasonics

Ultrasonic welding has emerged as a transformative technology within the UK filter manufacturing sector, offering substantial advantages over traditional methods like sewing. This advanced technique not only seamlessly bonds filter media together but also possesses the capability to cut and seal edges simultaneously, significantly enhancing efficiency and productivity.

Key Advantages of Ultrasonic Welding for Filters:

- Speed and Efficiency: Ultrasonic welding is notably faster than sewing, resulting in significantly reduced production times, increased output, and lower labour costs.

- Precise and Reliable Bonds: Ultrasonic welding creates robust, consistent, and airtight seals, ensuring optimal filter performance and preventing leaks.

- Versatility: This technology can be applied to a diverse range of filter types, including:

- Air Filters: HEPA filters, pleated filters, bag filters

- Liquid Filters: Cartridge filters, membrane filters, bag filters

- Medical Filters: Surgical masks, respirator filters, blood filters

- Industrial Filters: Dust collectors, process filters, wastewater filters

- Compatibility with Various Materials: Ultrasonic welding effectively bonds a variety of filter media materials, such as:

- Nonwovens: Meltblown, spunbond, needle-punched

- Wovens: Polyester, nylon, polypropylene

- Foams: Polyurethane, polyester, polyethylene

- Membranes: PTFE, polypropylene, nylon

Cutting-Edge Solutions from Sabre Plastics Tooling

Sabre Plastics Tooling specialises in the development and manufacture of high-quality tooling for the ultrasonic welding of filter media. As a leading UK supplier of Rinco ultrasonic welding equipment, we provide comprehensive solutions to meet the unique requirements of your filter manufacturing process.

Experience the Ultrasonic Advantage

By incorporating ultrasonic welding into your filter production line, you can:

- Enhance product quality: Achieve consistent and reliable seals, minimising leaks and enhancing filter performance.

- Increase productivity: Significantly reduce production time and labour costs.

- Enhance efficiency: Streamline your manufacturing process and optimise resource utilisation.

- Gain a competitive edge: Differentiate your products with superior quality and efficiency.

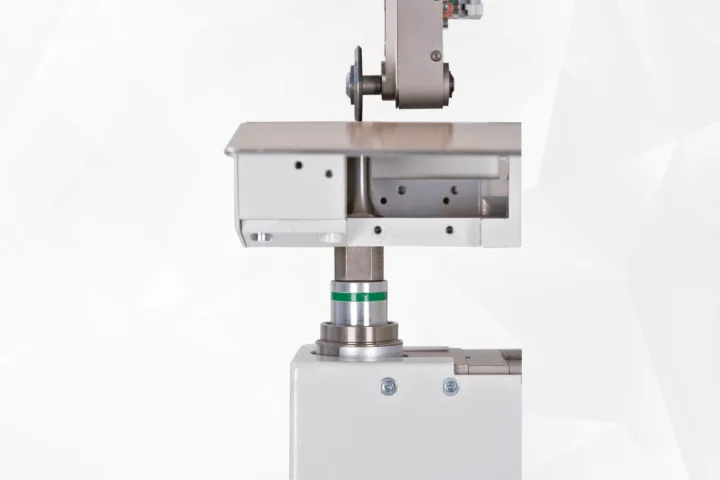

Ultrasonic Cutting Table

Ultrasonic Hand Cutters

https://www.rincoultrasonics.com/products/cutting-solutions/cutting-head-ch35

Contact Sabre Plastics Tooling today to learn more about how ultrasonic welding can revolutionise your filter manufacturing process.