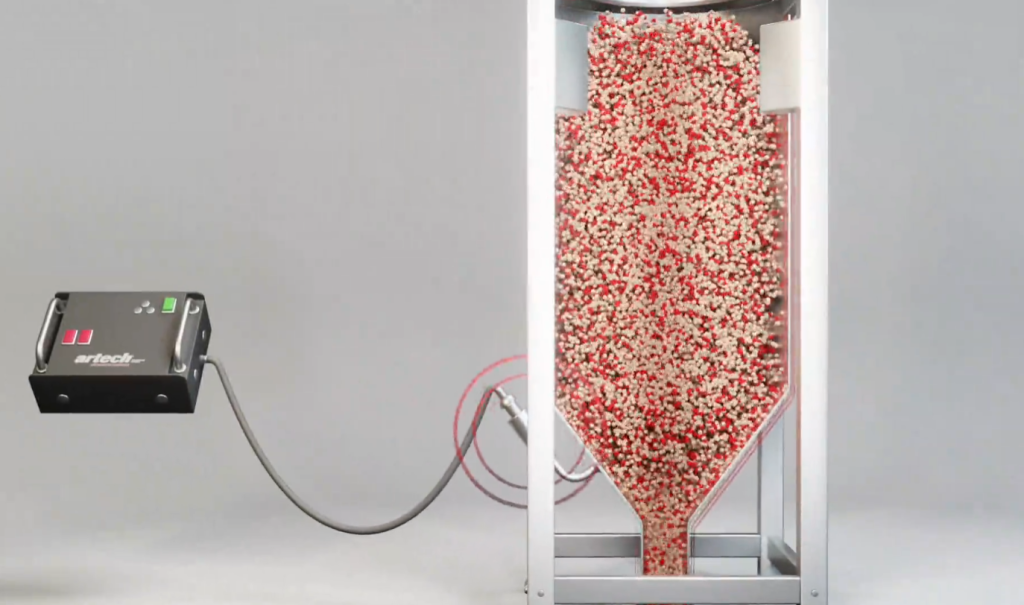

At Sabre, we offer state-of-the-art ultrasonic technology to enhance the flowability of bulk materials, effectively preventing common issues like bridging, ratholing, and segregation. Our solutions ensure continuous material flow, whether activated by a simple button press or an automated central control system. This not only minimizes system and employee stress but also promotes efficient and silent operations.

Key Advantages:

- Versatile Applications: Ideal for silos, hoppers, spray towers, mixing chambers, chutes, screw conveyors, and dosing units.

- Increased Efficiency: Enhances plant productivity by ensuring smooth, continuous flow and minimizing residual material.

- Cost-Effective: Reduces running costs with low energy consumption and minimal noise pollution.

Why Choose Sabre’s Ultrasonic Technology:

- Reliable Flow: Ultrasound minimizes static friction, ensuring uninterrupted material flow.

- Improved Productivity: Higher throughput and quality with reduced maintenance.

- Silent Operation: Protects employees and the environment with low noise levels.

Our ultrasonic solutions cater to various industries, including additive manufacturing, battery production, chemical and pharmaceutical sectors, paint production, and food processing. Whether you need retrofit solutions or new installations, Sabre’s ultrasonic technology offers an optimal, energy-efficient choice for managing bulk materials.

For tailored solutions and expert consultation, contact Sabre today. Let’s work together to optimize your material handling processes with our advanced ultrasonic systems.

View a recent Ultrasonic Discharging Case Study for the Flowsonic here.